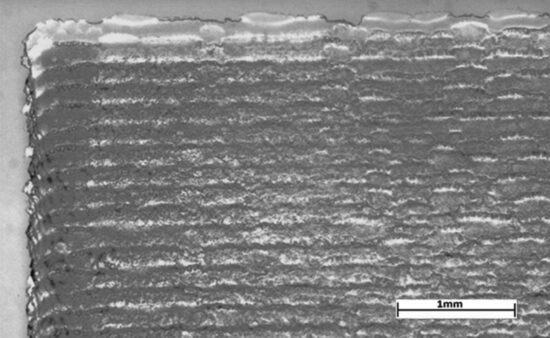

The development of an additive manufacturing process for the production of fully functional complex metal components.

Contact usThis multidisciplinary project has the overall aim of developing an additive manufacturing process for the production of fully functional complex metal components with low residual porosity and dimensional stability. The parts will be built from a range of structural materials, with more novel composites being investigate towards the end of the project. This aim will be achieved by replacing the organic sacrificial binder technology normally used with a novel approach developed at Liverpool University. This will require the formulation and application of new Reactive Metal Jet Fusion inks that combine Reactive Organometallic (ROM) inks with multi-scale micron and nano particle constituents.

EpiValence is proud to be supporting this project and providing expertise in organometallic chemistry to enable the development and subsequent commercialisation of new inks to support the technology roll out. The lead academic is Dr Kate Black and further details of the EPSRC funded project can be found at this link.