The study and development all aspects related to reactive inkjet printing of metal oxides.

Contact usThe use of metal oxides in many applications has been limited to vapour deposition or large area printing technologies to produce continuous thin films on the target substrate that require patterning to create the final functional product.

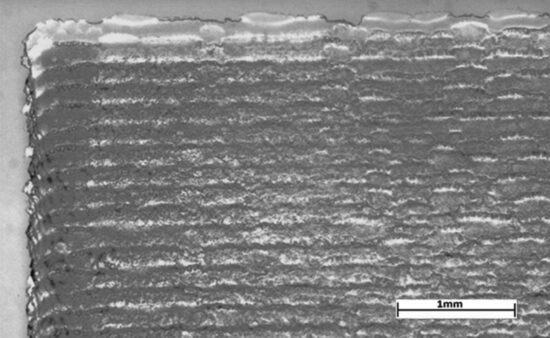

The use of inkjet printing offers the opportunity to directly create a patterned structure thus reducing processing steps and complexity. However, the chemistry needed to enable inject printing of metal oxides is in its infancy and requires significant effort to tailor precursors, formulations and process conditions to yield the target structures on a range of substrates. The objective of this project is to study and develop all aspects related to reactive inkjet printing of metal oxides with specific attention to demonstrating its advantages and capabilities compared to currently available processes.

EpiValence is sponsoring a PhD student (Josh Turner) to investigate Single element oxides, Mixed metal oxides, Doped metal oxides. In particular control of the component incorporation in the final film is to be addressed to allow facile movement between these systems to enable complex structures to be fabricated on demand. The collaborating academics are Dr Kate Black and Prof Helen Aspinall.